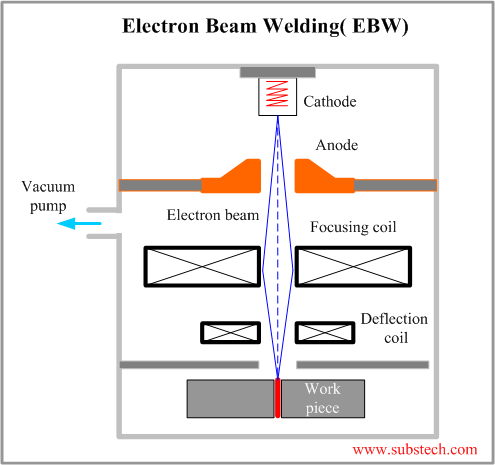

Electron beam welding is achieved by joining two components with a stream of high velocity electrons. These electrons are accelerating at a speed of more than 100,000 miles per second. This technique is better than conventional welding because it produces power intensities 5,000 times greater, since the beam of energy is concentrated to precisely 0.2mm or 0.010 inches in diameter. High repeatability is ensured with this method since it is governed with maximum control by a filament current.

The benefits of electron beam welding compared to conventional welding are precise control over penetration and dimensions, high level of repeatability, freedom from impurities and negligible distortion and shrinkage. This method is also known to be stress relieving thereby reducing the overall cost of producing the product. Upon applying this technique to their services, one company found this method to be very acceptable and also well received by their clients and prospective clients.

The benefits of electron beam welding compared to conventional welding are precise control over penetration and dimensions, high level of repeatability, freedom from impurities and negligible distortion and shrinkage. This method is also known to be stress relieving thereby reducing the overall cost of producing the product. Upon applying this technique to their services, one company found this method to be very acceptable and also well received by their clients and prospective clients.

According to many professionals, this method is preferred by manufacturers, specifically those working with precision machined component parts such as those in aerospace, pharmaceutical and automotive industries. Since this method requires precision and intricacy, often times, there is a problem with quality control. To address the issue, Vision Engineering has teamed up with Ravenscourt Engineering Limited to provide the necessary software and products, such as Vision ArchiVE and the Alpha stereo microscope, to make quality control a quick and easy process. Ravenscourt Engineering Limited, Senior Engineer, Martin Burridge, has provided the following statement:

The Alpha stereo mantis microscope from Vision Engineering provides us with an exemplary stereo image, brilliant contrast and superb clarity required for the inspection and measurement process. Coordinated with the use of a digital camera and the Vision's archiving and analysis software, enables us to digitise our findings, measure, analyse and generate a report for our quality control process. With the increase in orders and new projects, we need to be able to produce a comprehensive documenting system, providing us with a parameter to enforce a consistently high standard.

In example, Ravenscourt Engineering Limited applied the welding process to helicopter engine components. The tolerance band for depth penetration was very tight and thus, variations between batches were observed. Next, the coupon samples were split, examined, measured and documented making sure that the quality and accuracy of the weld was maximized. The Alpha stereo microscope and Vision ArchiVE software were then used to inspect as well as measure the coupon samples from the batches. Using both products produced a clear, high resolution image for easier archiving which cut the inspection and measurement process in half.

Then, the image captured is analyzed and documented using Vision ArchiVE. The Alpha stereo scienscope , meanwhile, is used to inspect the welded joins enabling the company to perform effectively to aerospace standards. These two products have greatly made the quality control process for electron beam welding easier with precise yet at the same time quicker imaging and archiving. With this technique, Ravenscourt Engineering Limited has proven their worth to their clients by providing fast and affective service with precise results. This in turn has encouraged their clients to commit to this expanding company for their subsequent and future projects.

No comments:

Post a Comment

Please lets's hear from you concerning your experience here with us. We will like to know how you feel about us.